Downtime is the enemy of productivity, and every hour your equipment sits idle costs thousands in lost output.

When critical components fail, removing them for off-site repair can mean days of lost production. That’s why many industrial operations now rely on on-site machining services – a fast and efficient solution that brings precision machining directly to your facility.

At HD Industries, we provide mobile machining solutions that minimize downtime and keep your systems running.

1. What is On-Site Machining?

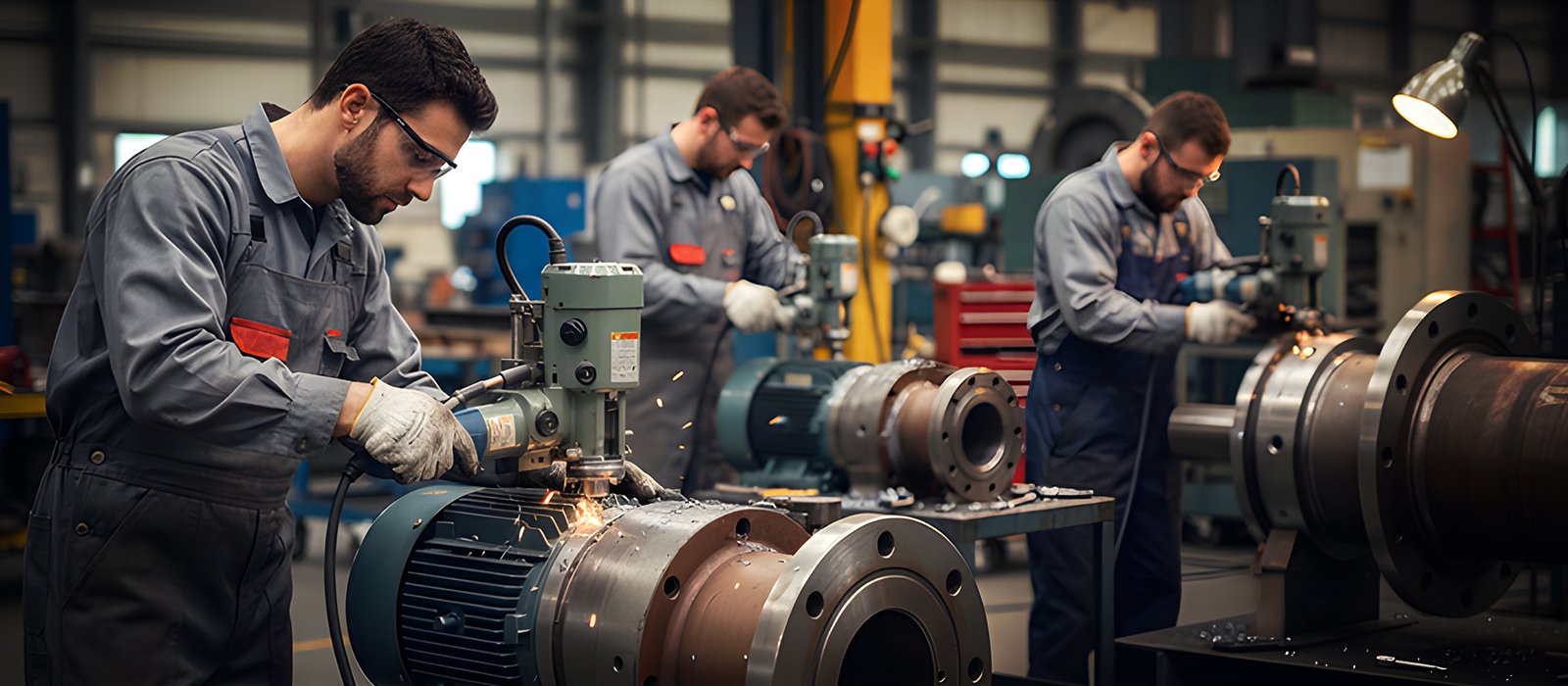

On-site machining, also known as field machining, enables technicians to carry out repairs, reconditioning, and precision work directly at your location.

HD Industries specialists can restore damaged surfaces, re-machine parts, or make modifications to existing equipment without disassembly and shipping using our portable milling, turning, and boring equipment.

2. Faster Turnaround, Less Downtime

The greatest advantage of on-site machining is speed. Instead of waiting for transport and shop scheduling, our technicians arrive quickly, assess the damage, and start work immediately.

This eliminates logistical delays and reduces downtime by up to 60–80% compared to traditional repairs; many clients resume production within hours instead of days.

3. Savings on Transportation and Labour Costs

It is highly expensive to disassemble heavy components and ship them for off-site repair. On-site machining reduces these costs dramatically. Our technicians execute the same high-precision work you’d expect from a full machine shop-without having to move your equipment. That means lower transportation costs and minimal production disruption.

4. Enhanced Accuracy and Performance

5. Energy Efficiency and Modern Technology

On-site machining reduces the risk of handling accidents during disassembly and transportation. It also reduces the environmental impact due to the elimination of unnecessary shipping and packaging. For facilities with sustainability goals, it is a win-win situation: safer, quicker, and greener operations.

Conclusion

On-site machining services are transforming the way industries manage maintenance and repair. Combining mobility, precision, and efficiency, HD Industries supports its clients in reducing downtime, saving money, and extending equipment life. Our team of experienced technicians can handle repair jobs of all sizes, from simple surface machining to complete restoration of equipment, at your facility in a safe and efficient manner.

Add a Comment