Description

Standards : 40CrMnNiMo8-6-4

P20+Ni

DIN 2738

AISI P20+Ni

| C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.35 – 0.45 | 0.20 – 0.40 | 0.60 – 1.00 | 0.03 | 0.03 | 1.80 – 2.10 | 0.15 – 0.25 | 0.90 – 1.20 |

Grade Brief:

P20+Ni is specially used for Plastic injection die moulds. The characteristics of a material are right sharpening, photo-etching properties with high purity and good homogeneity. P20+Ni is upgraded version of plastic mold steel 0f 2311, which normally supply in Pre hardened condition. Hardness in as supplied condition 280-320 HB with having uniform hardness. The additional nickel content of 1 % increases through hardening. It has good machinability, suitable for Texturing, fine polishability, adequate corrosion resistance, vacuum-degassed steel.

P20+Ni High Hard ( HXM 24 )

P20+Ni is with High Hardness 360-400 BHN and increase alloy elements to get extra life and outstanding polishing.

P20+Ni steel is a type of plastic mold steel that is similar to DIN 1.2738 / AISI P20+Ni Tool Steel. The alloying elements for hardness and toughness include nickel, chromium, and molybdenum. P20+Ni tool steel is intended specifically for the plastic mold industry, particularly for large steel mold components. P20+Ni tool steel is often provided pre-hardened/quenched and tempered in the 280 – 320 HB hardness range. This makes it a great choice for applications involving high-temperature settings and difficult mechanical conditions. P20+Ni steels have superior polishability compared to 1.2312 (AISI P20+S) and better machinability. To enhance the hardness and wearability of the mould surface material , it can be treated with nitrogenation and flame hardening. P20+Ni steel is melted in an electrical furnace and refined using a VOD or DH equipment.P20+Ni steel is a type of plastic mold steel that is similar to DIN 1.2738 /AISI P20+Ni Tool Steel. The alloying elements for hardness and toughness include nickel, chromium, and molybdenum. P20+Ni tool steel is intended specifically for the plastic mold industry, particularly for large steel mold components.

P20+Ni tool steel is often provided pre-hardened/quenched and tempered in the 280 – 320 HB hardness range. This makes it a great choice for applications involving high-temperature settings and difficult mechanical conditions.

P20+Ni steels have superior polishability compared to 1.2312 (AISI P20+S) and better machinability. To enhance the hardness and wearability of the mould surface material , it can be treated with nitrogenation and flame hardening. P20+Ni steel is melted in an electrical furnace and refined using a VOD or DH equipment.

Mode of Supply

HD-Industries is the largest stockiest and supplier of P20+Ni Steel in flat, square and round bar. We provide steel in all sizes as your requirements. P20+Ni die steel is available in flat, square and round shape. Consult our team who will assist you for P20+Ni steel query.

Steel Properties

P20 +Ni is upgrade version of plastic mold steel 0f 2311, which normally supply in Pre hardened condition. Hardness in as supplied condition 280-320 HB. The additional nickel content of 1 % increases through hardening. It is micro-alloyed. It has good machinability, suitable for texturing, outstanding polishability, adequate corrosion resistance. vacuum-degassed steel with the following excellent features.

Mechanical Properties:

| Tensile Strength | 850 MPa-1100MPa |

| Yield Strength | 770-980 MPa |

| Hardness | 235 HB |

| Elongation | 13%-16% |

| Impact Toughness | 20 J/cm2-42 J/cm2 |

| Modulus of elasticity | 205 x 10³N/mm2 |

Physical Properties

The physical properties can vary slightly depending on the specific composition and heat treatment of the P20+Ni /DIN 2738 /AISI P20+Ni steel. It’s always recommended to refer to the manufacturer’s specifications for precise information.

| Coefficient of thermal expansionat °C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 |

| 10-6 m/(m*K) | 11.2 | 12.8 | 13.5 | 13.7 | 14.3 | 14.7 | 14.9 |

| Thermal Conductivity at °C | 20 | 350 | 700 |

| W/(m*K) | 35 | 34 | 33 |

Heat Treatment & Processes:

Heat Treatment

P20+Ni / DIN 2738 / AISI P20+Ni is already pre-toughened, thus no heat treatment is necessary if no particular needs exist.

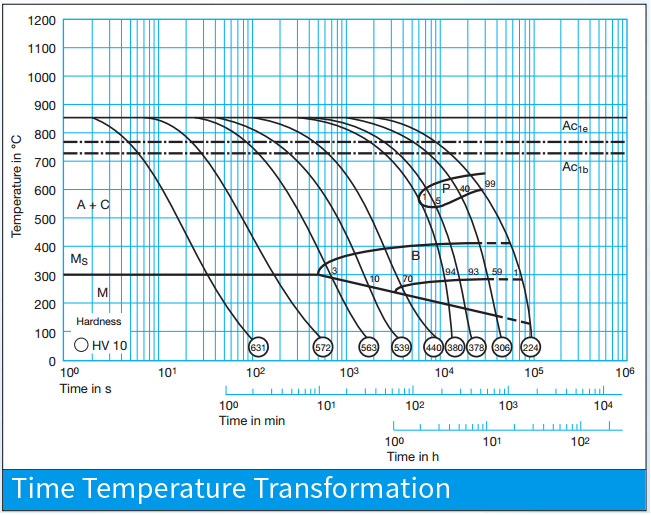

Hardening:

Harden from 840-870°C, followed by oil, and finally quench in oil/hot bath/air 180-220 °C. The hardness after quenching is approximately 52 HRC.

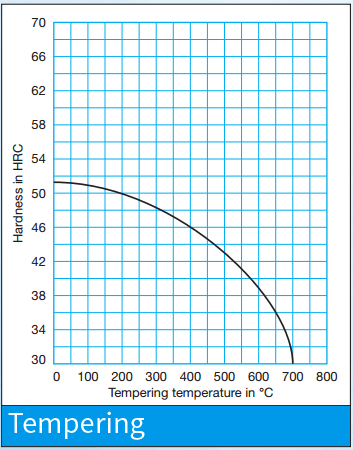

Tempering:

After hardening, slowly heat the part to the tempering temperature; the minimum duration in the furnace is one hour for every 20 mm of part thickness; two tempering is advised.

Forging:

1093-898 °C.

Stress Relieving:

Approx. 650°C.

Normalizing:

Approx 900°C

Annealing:

The maximum Brinell hardness will be 235 after being heated to 710 to 740 °C for 2 to 5 hours, and then gently cooled to 600 °C additional cooling in air.

Welding:

For the welding process , P20+Ni tool steel conventional methods are used.

Quenching:

840-870 °C.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 710 – 740 | Furnace | max. 235 |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 840 – 870 | Polymer or oil | 51 |

| Tempering °C after Quenching | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| HRC | 51.5 | 50.2 | 48 | 46.2 | 43 | 39 | 29 |

Application

P20+Ni is equivalent grade of most popular steel grade of DIN 2738 which is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.

Reviews

There are no reviews yet.