Description

HCHCR D3 / DIN 1.2080 / AISI D3 Tool Steel

| STANDARDS | X210CrW12 | HCHCR-D3 | DIN 2080 | AISI D3 | AFNOR Z210W12-01 | JIS SKD1 |

CHEMICAL COMPOSITION (Typical Analysis in %)

| C | Si | Mn | P | S | Cr |

| 2.00-2.35 | 0.10-0.60 | 0.20-0.60 | 0.030max | 0.030max | 11.00-13.00 |

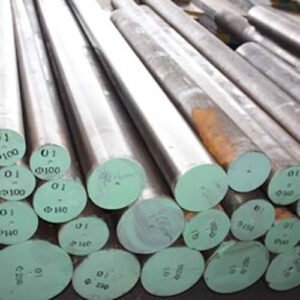

HD-Industries HCHCR D3 tool steel in India and abroad. D3 Steel have 12% ledeburitic chromium tool steel with great wear resistance. Basically it is used as cutting tools for sheets up to 4 mm thickness, blanking dies for paper and plastics, trimming dies, shear cutting edges and rotational shear edges for sheet thicknesses up to 2 mm.

STEEL PROPERTIES

D3 Steel contains properties of High Carbon 2% and High chromium 12 % tool steel with high wear resistance ability. Its supply condition is typically annealed to easy machining and its prescribed hardness is 57-58 HRC after making the dies and tools.

APPLICATION

HCHCR D3 tool steel is utilized in cold dies and tooling application which requires high degree (level) of accuracy in hardening and tempering. For example, dies drawing, forming cold rolls, blanking dies for paper and plastics, powder metal tooling and blanking & trimming dies, shear blades, ejector pins, cold die punches etc.

PHYSICAL PROPERTIES

| Coefficient of Thermal Expansion at °C | 10¯⁶ m / (m*K) |

| 20-100 | 10.7 |

| 20-200 | 11.6 |

| 20-300 | 12.3 |

| 20-400 | 12.6 |

| 20-500 | 12.9 |

| 20-600 | 13.2 |

| 20-700 | 13.3 |

| Thermal Conductivity at °C | W / (m*K) |

| 20 | 16.6 |

| 350 | 20.5 |

| 700 | 24.3 |

HEAT TREATMENT

| Soft Annealing °C | 810-850 | |

| Cooling | Furnace | |

| Hardness HB | max. 250 | |

| Stress-relief Annealing °C | approx. 670-720 | |

| Hardening °C | 940-970 | 950-980 |

| Quenching | Oil | Air (upto 30mm thickness) |

| Hardness after quenching HRC | 64.5 | 64.5 |

SIZE RANGE

ROUND – 8 to 450 MM | SQUARE – 11 to 155 MM

FLATS – THICKNESS : 6 TO 150 MM | WIDTH : 20 to 505 MM

Reviews

There are no reviews yet.