Description

HCHCR D2 KNL is a high-performance cold work steel known for its exceptional wear resistance, hardness, and durability.

At HD Industries, we specialize in providing premium HCHCR D2 KNL Cold Work Steel that ensures precision and long-lasting performance

for industrial applications. Whether you’re manufacturing dies, punches, or cutting tools, our HCHCR D2 KNL guarantees reliability in demanding conditions.

Cr12MoV Steel | SKD11 alloy steel

Description

Cr12MoV steel is a kind of ledeburite cold work tool steel which developed from Cr12 steel, as the added content of Mo, V, and decrease of C, Cr12MoV have the advantage of Higher hardenability, hardness, wear resistance and small heat treatment distortion. It’s regularly be used in manufacturing cold mold with a heavy load, bulk production, and complex shape. Due to Cr12MoV is ledeburite steel, so its toughness is greatly influenced by the carbide morphology and distribution.

Cr12MoV Steel, steel hardenability, quenching and tempering the hardness, wear resistance and strength than that of high Cr12. Cross section used in the manufacture large, complex shape, working under arduous conditions, with a variety of Die and tools, such as die punching, trimming mold, piping die, deep drawing steel mold, circular saws, standards, tools and gauges, thread rolling die and so on.

Chemical composition% of Cr12MoV steel

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | V(%) | Cu(%) |

| 1.45~1.70 | ≤0.40 | ≤0.40 | ≤0.030 | ≤0.030 | 11.00~12.50 | ≤0.20 | 0.40~0.60 | 0.15~0.30 | ≤0.30 |

Cr12MoV equivalents alloy steel

| Steel | Country Code | C(%) | V(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) |

| SKD11 | CNS | 1.4-1.6 | 0.2-0.5 | ≦0.4 | ≦0.6 | ≦0.03 | ≦0.03 | 11.0-13.0 |

| Cr12MoV | GB | 1.45-1.70 | 0.15-0.30 | ≦0.4 | ≦0.4 | ≦0.03 | ≦0.03 | 11.0-12.5 |

| SKD11 | JIS | 1.4-1.6 | 0.2-0.5 | ≦0.4 | ≦0.6 | ≦0.03 | ≦0.03 | 11.0-13.0 |

| X165Cr-MoV12 | DIN | 1.55-1.75 | 0.1-0.5 | 0.25-0.40 | 0.2-0.4 | ≦0.03 | ≦0.03 | 11.0-12.0 |

Cr12MoV steel Range of products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

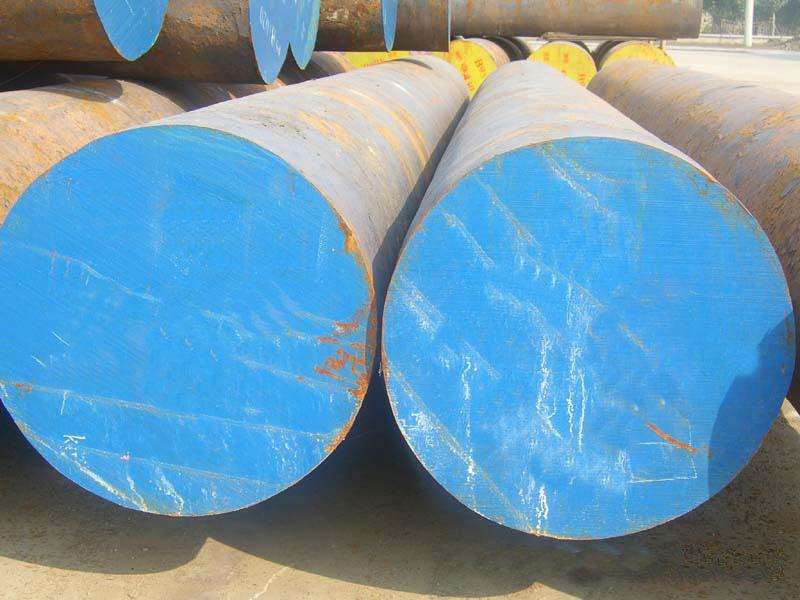

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Heat treatment of Cr12MoV Alloy Steel

spheroidizing annealing:860℃ X 2h furnace cooling to 750℃ and then furnace cooling to 500-550℃, remove out and air cooling

Quenched + tempered:1100℃ X 20min step quenching + 700℃ X 1h tempering,remove out and air cooling

Quenching:1030℃ X 40min oil quenching(800℃ preheating,vacuum 2.5 pa) Tempering: 250℃ X 1h

Application

Cold work dies steel, steel hardenability, quenching, and tempering hardness, wear resistance, strength is higher than Cr12. Used in the manufacture of various cold stamping dies and tools with large cross- sections, complex shapes and heavy working conditions, such as punching die, trimming die, piping dies, deep drawing dies, circular saw, standard tools, and gauges Thread rolling die, etc.

HCHCR D2 KNL / Cr12MoV Cold Work Steel – HD Industries

The Ultimate Cold Work Steel for Tough Applications

When it comes to high-performance tool steel, HCHCR D2 KNL / Cr12MoV stands out for its exceptional wear resistance, high hardness, and toughness.

At HD Industries, we specialize in providing premium Cold Work Steel that ensures durability and precision for industrial applications.

Whether you’re manufacturing dies, punches, or cutting tools, our HCHCR D2 KNL / Cr12MoV guarantees long-lasting performance.

What is HCHCR D2 KNL / Cr12MoV Steel?

HCHCR D2 KNL / Cr12MoV is a high-carbon, high-chromium tool steel designed for demanding applications where wear resistance and durability are essential.

With enhanced toughness and excellent heat treatment properties, this steel is widely used in cold stamping, cutting, and industrial tooling.

- ✔️ Superior Hardness – Perfect for precision tools that require a sharp edge

- ✔️ High Wear Resistance – Withstands extreme pressure and heavy-duty applications

- ✔️ Excellent Toughness – Reduces chipping and increases tool life

Key Features of HCHCR D2 KNL / Cr12MoV Cold Work Steel

1. High Hardness & Strength

This steel is engineered for extreme durability, making it perfect for industrial cutting and forming applications.

2. Superior Wear Resistance

With high chromium content, HCHCR D2 KNL / Cr12MoV resists wear and deformation even under high stress.

3. Exceptional Heat Treatment Response

This steel maintains dimensional stability and hardness after heat treatment, ensuring precision and longevity.

Applications of HCHCR D2 KNL / Cr12MoV Cold Work Steel

🔹 Tool & Die Manufacturing

Ideal for making dies, punches, and forming tools that demand high wear resistance.

🔹 Industrial Machinery Components

Used for high-load machine parts that require extreme durability and toughness.

🔹 Cutting & Stamping Tools

Perfect for shear blades, slitting tools, and industrial cutters, ensuring long-lasting sharpness.

Why Choose HD Industries for HCHCR D2 KNL / Cr12MoV Steel?

- ✅ Industry Experts Since 1967 – Over 50 years of experience in steel trading

- ✅ High-Quality Assurance – Sourced from top manufacturers for reliability

- ✅ Fast & Reliable Supply – Nationwide delivery for bulk and custom orders

Get High-Quality HCHCR D2 KNL / Cr12MoV Cold Work Steel Today!

Looking for premium Cold Work Steel HCHCR D2 KNL / Cr12MoV?

HD Industries provides top-grade steel for precision tools and industrial applications.

Contact us today for expert advice and competitive pricing! 🚀

–>

Reviews

There are no reviews yet.