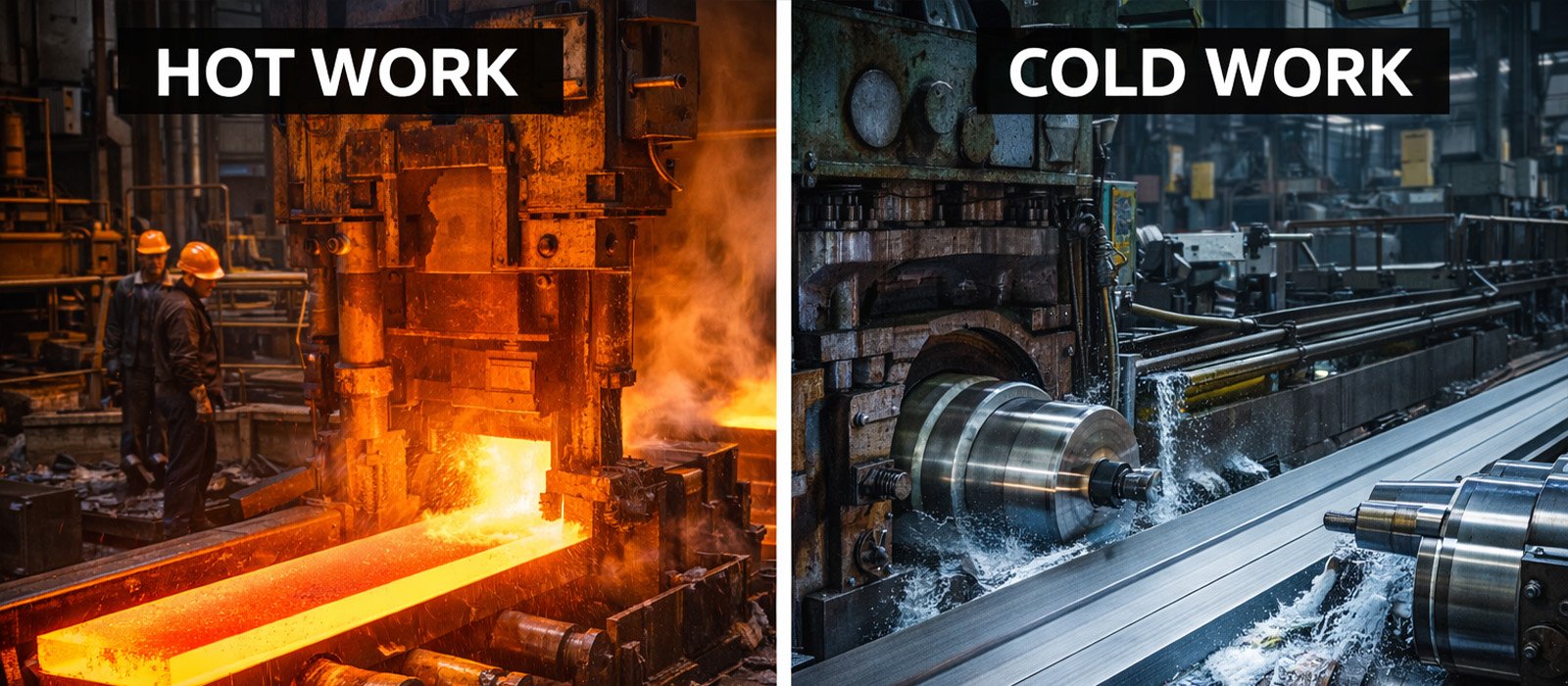

Tool steel is the backbone of manufacturing. But choosing between hot work and cold work tool steel can be confusing.

1. What Is Hot Work Tool Steel?

Hot work tool steel is designed to withstand high temperatures, making it ideal for forging and extrusion.

Key Benefits

- High thermal resistance.

- Excellent toughness.

- Long service life in hot environments.

2. What Is Cold Work Tool Steel?

Cold work tool steel is used at lower temperatures, perfect for cutting, stamping, and pressing.

Key Benefits

- Superior wear resistance.

- High hardness.

- Precision in steel cutting tools.

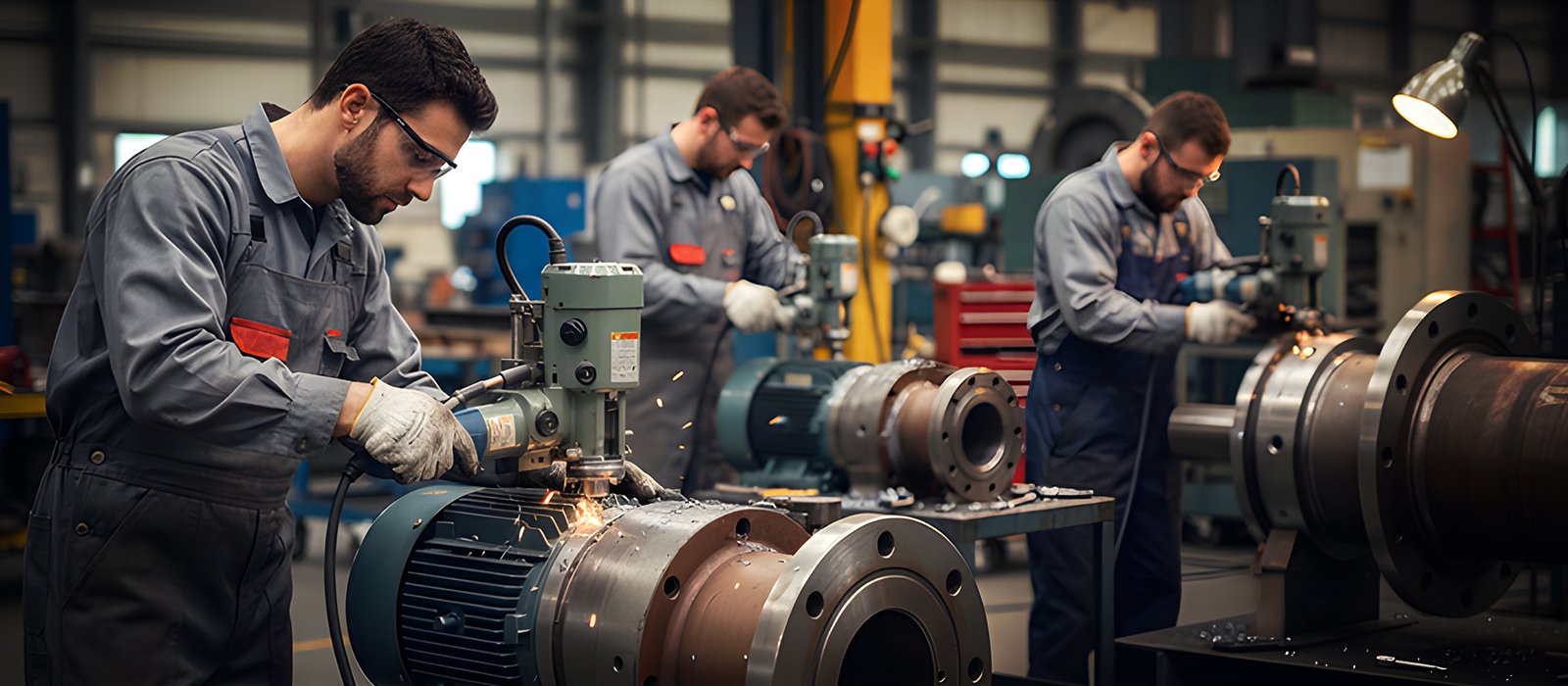

3. Choosing the Right Steel

The choice depends on your application:

- Hot work for high-heat processes.

- Cold work for precision cutting and stamping.

Conclusion

Whether you need hot work tool steel for forging or cold work tool steel for cutting tools, HD Industries provides the right solution backed by expertise and trust.